Cast with Confidence:

Your Pressure Die Casting Partner

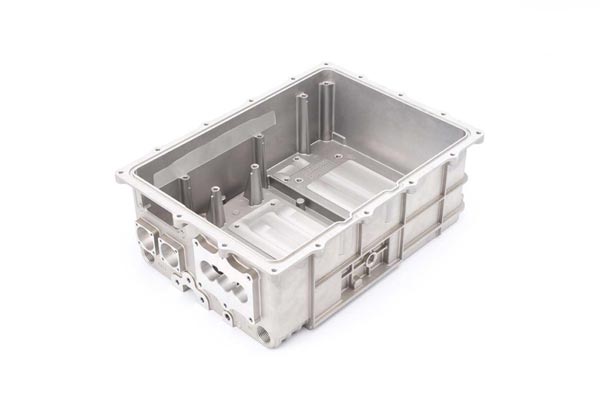

Elevate your production with our pressure die casting services. With precision and expertise, we specialize in creating high-quality, intricate parts using advanced die casting techniques. From concept to completion, trust us to deliver superior results with efficiency and reliability. Cast with confidence and bring your designs to life with our pressure die casting solutions.

Pressure Die Casting

Beisi Rapid pressure die casting services—a cornerstone of precision manufacturing. Utilizing advanced techniques and state-of-the-art technology, we specialize in crafting high-quality, intricate parts with exceptional accuracy and efficiency. From concept to completion, our expert team ensures superior results that meet the most demanding specifications. Trust us to bring your designs to life with precision and reliability.

Advantages of Die Casting

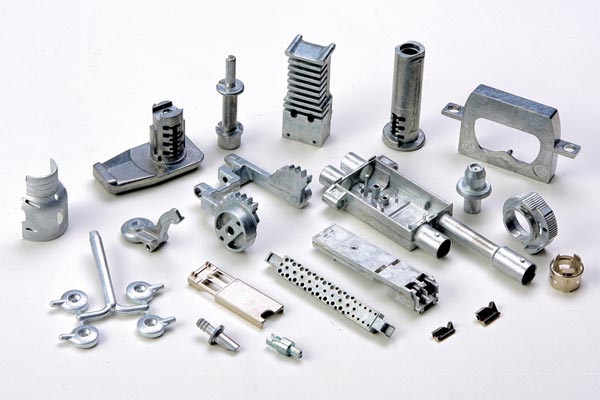

- Precision and Accuracy: Pressure die casting offers exceptional dimensional accuracy and repeatability, allowing for the production of complex parts with tight tolerances.

- Cost-Effectiveness: With high production rates and minimal post-processing requirements, pressure die casting provides a cost-effective solution for large-scale manufacturing.

- Versatility: Pressure die casting can be used with a variety of metals and alloys, offering flexibility in material selection for diverse applications.

- Strength and Efficiency: Die-cast parts exhibit excellent mechanical properties, such as high strength-to-weight ratios and durability, while the automated processes ensure high production efficiency and reduced lead times.

Get a Quote with Fast Respone

Take to Our Engineer About Your Project Requirements

Place an Order

Process of Pressure Die Casting

Tool Preparation

The process begins with the preparation of the die casting tool, which consists of two steel molds (or dies) that are precisely machined to form the desired part shape. These molds are typically made of hardened steel to withstand the high pressures and temperatures involved in the casting process.

Melting

The next step involves melting the chosen metal or alloy in a furnace to its liquid form. The temperature is carefully controlled to ensure proper flowability and consistency of the molten metal.

Injection

Once the metal reaches the desired temperature, it is injected into the die cavity at high pressure using a hydraulic or mechanical press. The pressure forces the molten metal to fill the entire cavity and form the shape of the desired part.

Solidification

After injection, the molten metal rapidly cools and solidifies within the die cavity, taking on the shape of the mold. Cooling channels within the dies help to speed up the solidification process and ensure uniform cooling throughout the part.

Ejection

Once the part has solidified, the dies are opened, and the newly formed casting is ejected from the mold cavity using ejector pins or other mechanical means. The casting may undergo further trimming or finishing operations to remove any excess material or imperfections.

Trimming and Finishing

Finally, the casting is trimmed to remove any excess material or flash, and any additional finishing operations, such as machining, polishing, or coating, may be performed to achieve the desired surface finish and dimensional accuracy.

Overall, pressure die casting is a highly efficient and versatile manufacturing process used to produce high-quality, complex metal parts with tight tolerances and excellent mechanical properties.

Talk To Us About Your Next Project

Beisi Rapid

Precision CNC machining allows designers, R&D teams, and manufacturers who rely on components supply to create complicated products without further machining.

Services

Contact Beisi

Address

Room 202, 2nd Floor, No. 53 Huanmao Road,

Xuecun, Torch Development Zone, Zhongshan City

Instant Call

+86 153 9880 0243