Precision Unleashed:

Your 5-Axis CNC Machining Solution

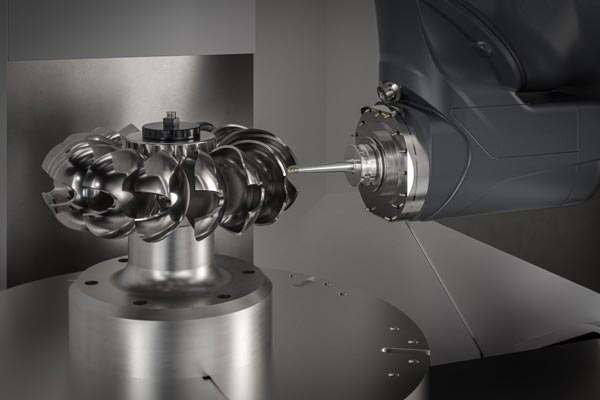

Experience the pinnacle of precision with our 5-axis CNC machining services. Utilizing advanced technology and expert craftsmanship, we specialize in delivering complex and intricate parts with unparalleled accuracy. From rapid prototyping to high-volume production, trust us to unlock the full potential of your designs with efficiency and reliability. Choose precision, choose excellence—choose our 5-axis CNC machining solutions for your manufacturing needs

High Quality CNC Machining

5-axis CNC machines provide unmatched versatility and speed for complicated and time-sensitive manufactured products. The fundamental components, existing parts, and systems serve as the foundation for CNC machine manufacture, which develops – new designs – in response to user needs. The design’s main elements get chosen as indicated here – A step motor (X, Y, Z), A step motor (A, B), the spindle motor, Stepper motor driver, Ball screws in linear motion, Timing belts, and Controller. The tool used in 5-axis machining can travel in 5 different directions, which correspond to the three linear axes (X, Y, and Z), plus two additional axes (A and B), around which the tool revolves. With this setup, the part may get worked from five different sides in one operation and all directions.

Why use 5 Axis CNC Machine for you projects

When using 5-axis machines, you may mill the workpiece from all sides, eliminating the need for manual rotation. Higher yields, better accuracy, and more mobility are all benefits of 5-axis machining that makes it possible to produce parts more quickly. 5-axis machinery can streamline your production processes, whether you’re delivering sophisticated equipment for a high-end aerospace project/straightforward components for a car marketed to consumers. While other projects can profit from the labor and error savings, some will require the advanced capabilities that the additional two axes give. Even more possibilities for what you can manufacture might arise with a 5-axis machine.

The tolerance of 5 axis CNC machine that we can adviced

When determining product measurements, engineering tolerances must get included. The parts are typically built to a broad tolerance grade unless the customer requests any specific tolerances. The minimum and maximum values that can get used for a dimension are how we define the limit tolerance. For use in the assembly, the manufactured components’ matching dimensions – should be located between these two positions. We only define the range of values in one direction for unilateral tolerance. We only permit variation from the nominal value on one side, in other words. Bilateral tolerance refers to the ability of a part’s final measurements to fluctuate on either side of its negligible value or actual profile. A step up from standard dimension tolerances is geometric dimensioning and tolerancing (GD&T).

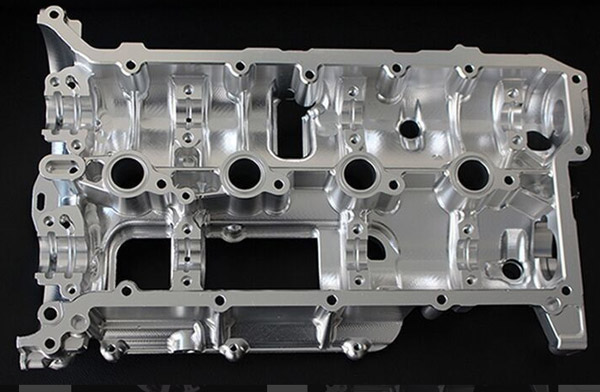

What parts that we can make with 5 Axis CNC machining

Five-axis CNC machines were previously solely used in the aerospace industry and utilized across many industries. Anywhere a three-axis CNC machine is present, a five-axis CNC machine can get used for a better finish and greater efficiency. Five-axis CNC machine CAM and CAD software could be very sophisticated. This machining behemoth uses the five-axis CNC machining’s ability to produce curved edges and smooth surfaces for aerospace applications. The majority of geometrically challenging and original applications are in aerospace. A five-axis CNC machine’s capacity to generate fine detail and perform interior cuts is of incalculable value. Medical Five-Axis CNC Machining Manufacturers of medical devices can benefit from CNC machining. The best degree of precision it provides can assist in producing implants, devices, and other parts that meet strict healthcare standards. Five-axis CNC machines get used to producing precision military device parts. In addition to their use in aerospace, they can get used in nuclear weapons, submarine parts, compressor blades, sensors, weapons, and high-performance engine parts. A five-axis CNC machine can create the specialized, intricate pieces required for energy equipment. A five-axis CNC machine may provide tranquility to a work area – when working with extremely tough, irregular materials, making shaping and cutting easier.

Talk To Us About Your Next Project

CNC Center of Beisi Rapid Factory

Beisi Rapid

Precision CNC machining allows designers, R&D teams, and manufacturers who rely on components supply to create complicated products without further machining.

Services

Contact Beisi

Address

Room 202, 2nd Floor, No. 53 Huanmao Road,

Xuecun, Torch Development Zone, Zhongshan City

Instant Call

+86 153 9880 0243