Generally, vacuum casting has lower tooling costs, so it works better for prototyping and short runs. Injection molding has higher startup costs but excels at high-volume production and consistency. Here is a comparison of vacuum casting and injection molding:

Vacuum Casting:

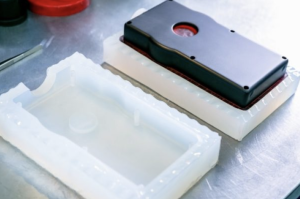

- The process involves pouring a liquid resin into a silicone mold and then placing the mold in a vacuum chamber to remove air bubbles. This helps ensure a good surface finish and detailed reproduction of mold details.

- It is typically used for short prototype runs or small production runs of 10-few hundred parts. It’s not ideal for high-volume production.

- Vacuum casting is an excellent choice for parts with tight tolerances and a smooth surface finish.

- Tooling costs are lower than injection molding as only a silicone mold is required, with no need for steel tooling.

- Generally slower cycle times than injection molding. Each part needs to be poured and vacuumed individually.

- Unlike injection molding, vacuum casting does not require a DFM process, allowing for project time savings.

Injection Molding:

- Thermoplastic or thermoset granules are melted and injected into a steel mold under high pressure.

- The best process for high volume, mass production part runs into the thousands or millions.

- Injection molding is best suited for parts with less stringent tolerance requirements.

- Very high initial tooling costs for machined steel molds.

- With fast cycle times. It’s an automated process that allows for high-volume output.

- A range of thermoplastic and thermoset materials are available for property requirements.

- High initial costs make it unsuitable for prototype volumes

If you have any Vacuum casting and injection molding project, please feel free to contact: joyce@beisi-rapid.com.