Model or part sample, small batch there are many ways to implement, which is more suitable for the customer ? Shortcomings of 3D printing, CNC machining and silicone reproduction are as follows:

CNC Machining:

Features: Material performance is good, the surface can paint, electroplating, and other processes, durable, can be collected screws.

A deficiency; Processing is difficult to clear the Angle in place, need manual programming and post-manual processing or electric spark, workload, high price and cost. The processing speed of small parts is slow

Mainly for customers: high degree requirements, high appearance requirements, strength and temperature resistance requirements, suitable for the structure of the workpiece processing is not too complex.

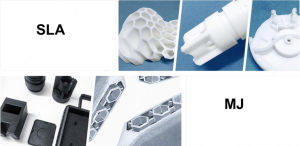

3D Printing:

Features: Strong structure, inverted, internal cross can be processed, manual processing is relatively simple. The processing speed of small parts is fast

Shortcomings: brittle, easy to break, not good bonding, oil injection effect is not very beautiful, can not be electroplated, the screw is explosive;

Suitable for making complex structure of digital products, and the appearance of the surface and strength of the small case product samples;

Metal 3D Printing

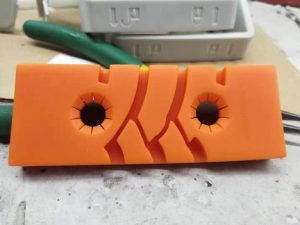

Vacuum Casting:

General material performance, surface spray effect is good, can do CNC and 3D printing can not do soft rubber products, can electroplating, screw collection. Viscose water,

Disadvantages: must be provided by 3D, or CNC prototype, single set of high cost, suitable for small batch replication, replication speed, accuracy requirements are not high occasions;

Suitable for small batch products large, small and soft rubber waterproof ring have advantages;

Which products are suitable for vacuum casting:

Personalized products, small demand, more complex structure, open traditional steel mold is not cost-effective products, such as auto parts, robots, medical instruments, 3C electronic products.

If you have any Rapid prototyping and Rapid Tooling, Please feel free to contact: joyce@beisi-rapid.com to get free quote.